No Touch Tool

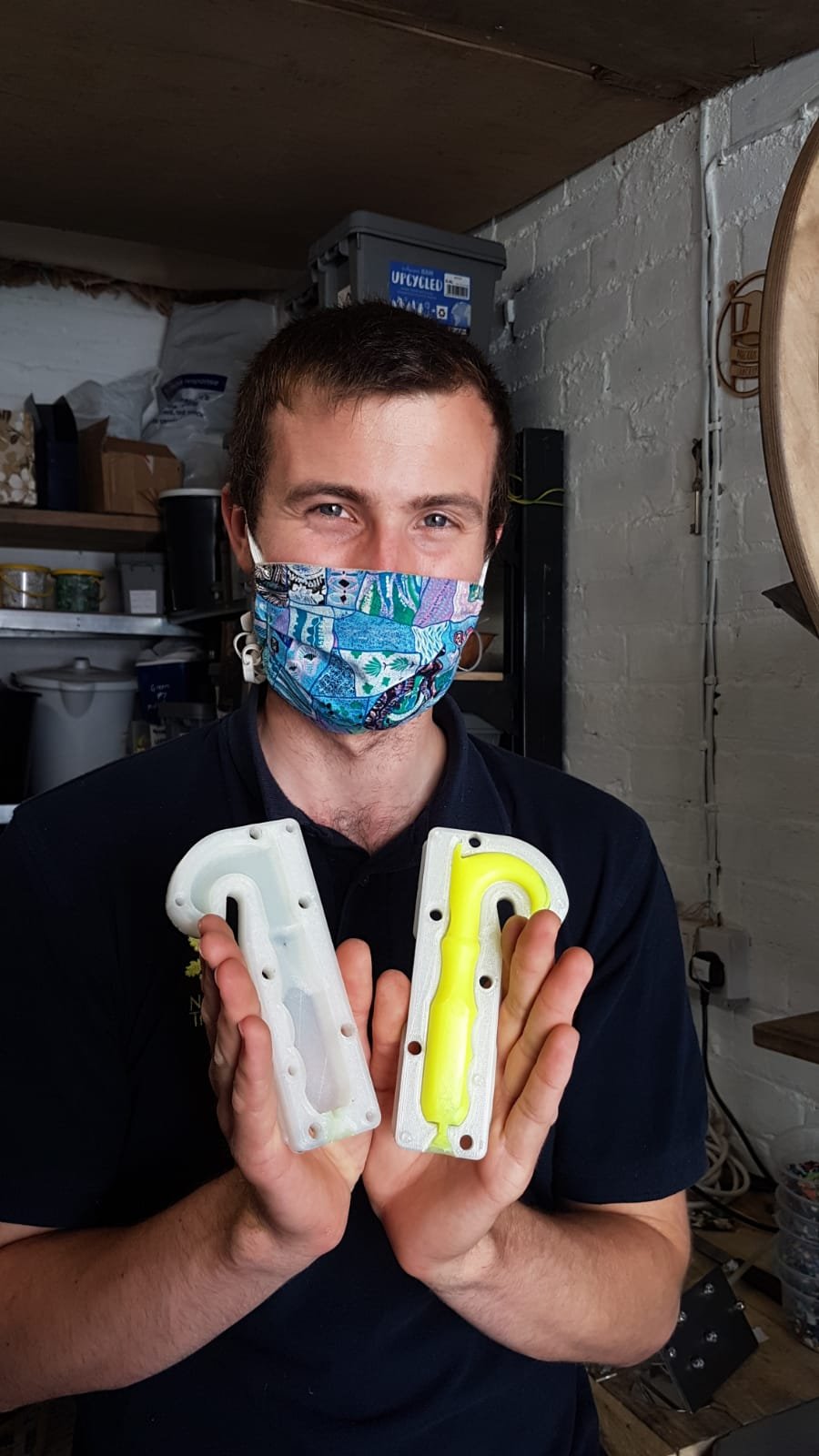

In June 2020 we thought about making a tool that would help keep people - especially our friends who were first responders and food package deliverers - safe from contact with surfaces that could be contaminated with Covid-19. Martin created a few prototypes with cardboard, then 3D printed a few iterations for our friends to test in the field. They all came back with requests and suggestions, another round of changes, and the ‘No Touch Tool’ was born. We had an idea to usable product within a week. A ‘perfected’ product within two, and began producing them as well.

There was interest from a number of international businesses who pushed for us to order a commercial injection mould in order to have them produced at a large scale. This would have required an initial investment of ~£5,000 in set up fees (traditional injection moulding requires capital to get started) and due to Covid-19 shortages and transportation delays, a mould would have taken approximately 2 months to arrive. Instead of investing in the high set up fees, we decided to 3D print 8 No Touch Tool moulds. In the 2 months we would have waited for a mould, we were able to produce 550 No Touch Tools for Checkpoint Safety, a local business that provided us with the plastic waste to create them, as well as opened up sales to the local public at locations throughout town at local coffee shops Brew and Holm, Single Step, through our website, and the Precious Plastic Bazar. We were even featured in the Lancaster Guardian.

In July of 2020 we created a How-To for the Precious Plastic community so anyone in the world could make their own because we love the idea of distributed design and the open source network Relic was built on.